बुध्दिमत्ता पूर्ण सामग्री और प्रगत प्रक्रियाएँ

स्मार्ट और कार्यात्मक सामग्री समूह, 12वीं पंचवर्षीय योजना परियोजना के हिस्से के रूप में एसएमए का उपयोग करके शेप (आकार) मेमोरी मिश्र धातुओं और एक्चुएटर विकसित करने पर काम कर रहा है। इसके अलावा एसएमए के समूह ने बहु-कार्यात्मक सामग्रियों को जोड़ने और बनाने के विकास के लिए पल्स पावर बनाने की तकनीक और उसके सिमुलेशन का विकास का काम किया है। भौतिक विज्ञान से लेकर धातु विज्ञान और सामग्री विज्ञान पृष्ठभूमि जैसी विभिन्न धाराओं के एसीएसआईआर के वैज्ञानिकों, तकनीकी अधिकारियों और पीएचडी छात्रों का एक मजबूत समूह, अगली पीढ़ी की कार्यात्मक सामग्री और प्रसंस्करण तकनीकों पर एक साथ काम कर रहा है। विभाग द्वारा किये जा रहे कुछ कार्यों का वर्णन यहां नीचे दिया गया है:

इंजीनियरिंग अनुप्रयोगों के लिए थर्मो रेस्पॉन्सिव और चुंबकीय आकार मेमोरी सामग्री और उपकरणों का डिजाइन और विकास

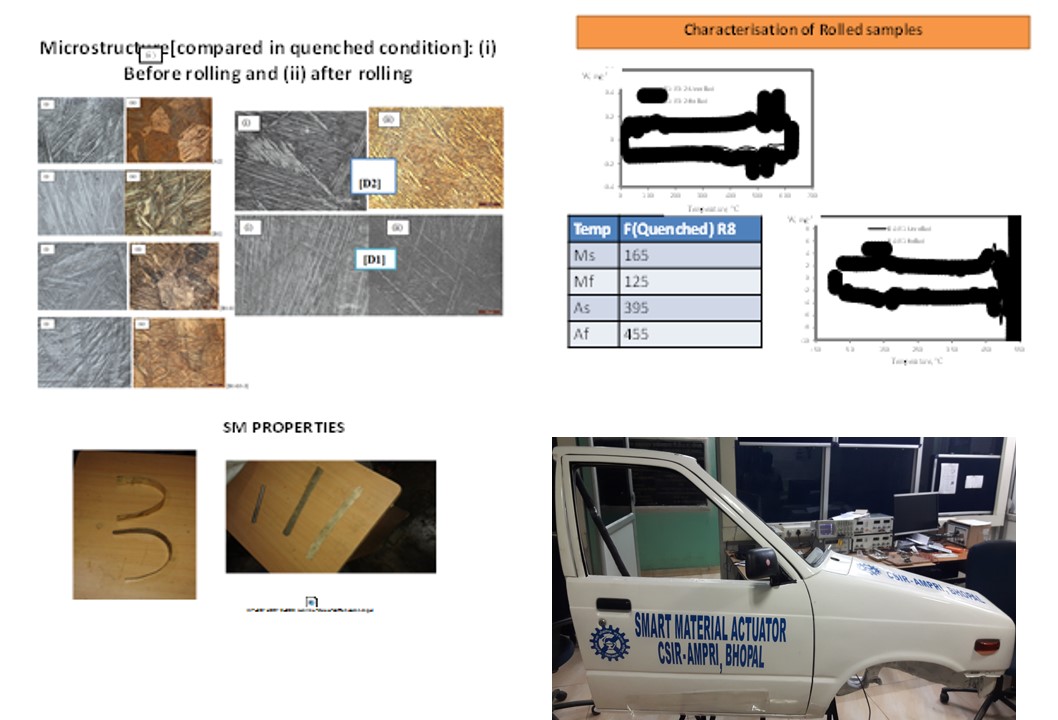

अलग-अलग मिश्र धातु प्रणालियों जैसे कि Cu-Al-Ni, Cu-Al-Mn और Cu-Zn-Al के साथ विभिन्न मिश्रधातु परिवर्धन और अनाज रिफाइनर के साथ रचनाओं का एक पूरा सेट बनाया गया है और उन स्थितियों को अनुकूलित किया गया है जिनके तहत वे सर्वोत्तम आकार स्मृति गुणों का प्रदर्शन करते हैं। निष्कर्ष उचित मिश्रधातु परिवर्धन और ताप उपचार के माध्यम से चयनित मिश्रधातुओं में मार्टेंसाइट गठन, उच्च संक्रमण तापमान और लंबे समय तक बनाए रखने जैसे आकार स्मृति गुणों में सुधार की संभावना की पुष्टि करते हैं। उच्च परिवर्तन तापमान तक पहुंच गया है और जिन नमूनों में क्षमता दिखी है उन्हें स्ट्रिप्स में रोल किया गया है। तार खींचने की मशीन खरीदकर लगा दी गई है। गुणों के साथ आकार स्मृति उत्पाद बनाने की क्षमता वाले मिश्र धातुओं का एक संपूर्ण डेटा बैंक तैयार किया गया है।

दरवाजे, पेट्रोल टैंक और डिकी ओपनर्स जैसे ऑटोमोबाइल के लिए एक्चुएटर्स बनाए गए हैं और वायवीय एक्चुएटर्स की जगह नितिनोल तारों का उपयोग करके परीक्षण किया गया है। बाद में व्यावसायिक रूप से उपलब्ध तारों को सीएसआईआर-एएमपीआरआई, भोपाल में विकसित एसएमए तारों से बदल दिया जाएगा। वर्तमान में और उपरोक्त उपलब्धियों के आधार पर, वांछित आयामों के Cu-आधारित SMA तारों/स्ट्रिप्स का निरंतर और बैच उत्पादन किया जा रहा है, जो CSIR-AMPRI द्वारा विकसित SMA तारों से एक्चुएटर्स के निर्माण में परिणत होगा।

पल्स पावर फॉर्मिंग (विद्युत चुम्बकीय विनिर्माण)

विद्युत चुम्बकीय विनिर्माण

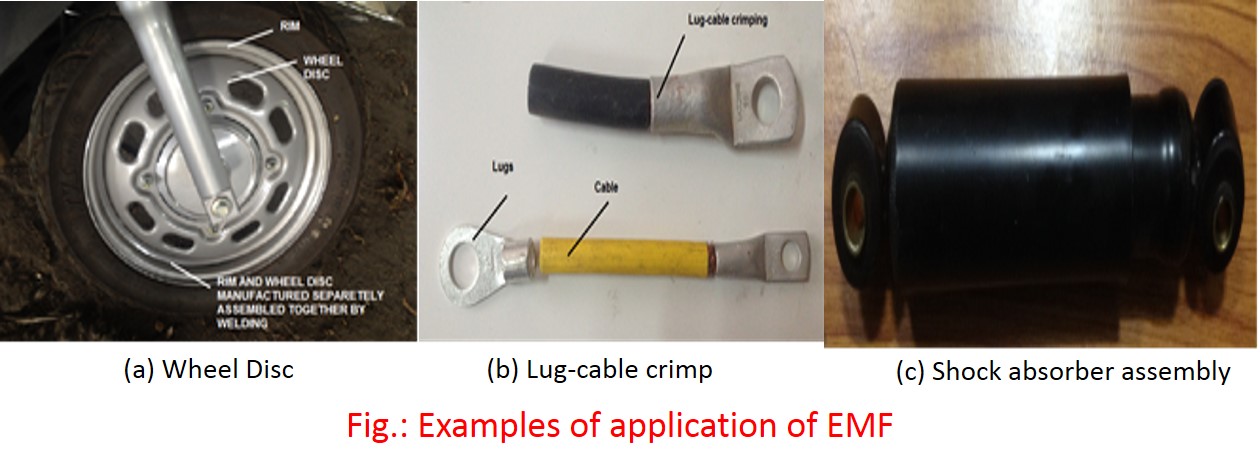

हाल ही में एएमपीआरआई ने 40 केजे, 20 केवी इलेक्ट्रोमैग्नेटिक फॉर्मिंग मशीन (चित्र 1) खरीदी है। यह मशीन 15 किलोहर्ट्ज़ आवृत्ति तक संचालित की जा सकती है और इलेक्ट्रोमैग्नेटिक फॉर्मिंग/ज्वाइनिंग (ईएमएफ) और इलेक्ट्रो हाइड्रोलिक फॉर्मिंग एप्लिकेशन के लिए उपयुक्त है। यह सुविधा हमें धातु बनाने और जोड़ने में नए अनुप्रयोग पर काम करने में सक्षम बनाएगी। यह उच्च तनाव दर तकनीक फॉर्मेबिलिटी, स्प्रिंगबैक, रिंकलिंग, ड्रॉएबिलिटी और जॉइनबिलिटी, उत्पादकता, नो एचएजेड आदि के मामले में पारंपरिक तरीकों से श्रेष्ठ है। इसे अनुसंधान संस्थान, ऑटोमोबाइल, एयरोस्पेस, परमाणु, घरेलू उपकरणों और बिजली क्षेत्र में लागू किया जा सकता है। अनुप्रयोग के कुछ विशिष्ट उदाहरण चित्र 2 में दिखाए गए हैं। बीएचईएल, आरआरसीएटी (आरआर केट) और अन्य उद्योगों के साथ नई परियोजनाएं शुरू की जा रही हैं। व्यावहारिक और बुनियादी दोनों तरह के शोध किए जा रहे हैं।

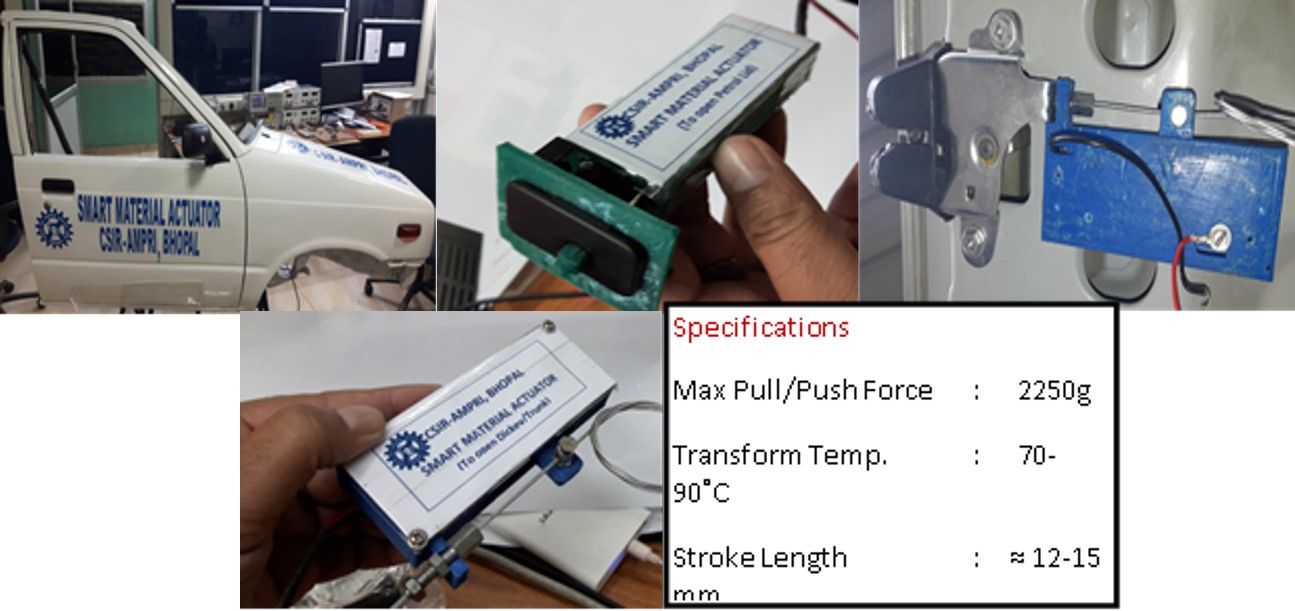

स्मार्ट मटेरियल एक्चुएटर

ऑटोमोबाइल/वाहन अनुप्रयोगों के लिए स्मार्ट सामग्री एक्चुएटर्स; डोर लैच असेंबली को लॉक-अनलॉक करने के लिए एक्चुएटर्स, फ्यूल फिलर डोर/पेट्रोल ढक्कन रिलीज एक्चुएटर और डिकी लैच रिलीज एक्चुएटर सिस्टम विकसित किया गया। शेप मेमोरी मटेरियल स्मार्ट मटेरियल [धातु, पॉलिमर और सिरेमिक] का एक व्यापक वर्ग है जो एक उपयुक्त उत्तेजना लागू होने तक अपना आकार बनाए रखने में सक्षम होते हैं जिसके बाद वे अपने मूल आकार को पुनः प्राप्त कर लेते हैं। आकार स्मृति प्रभाव (एसएमई) गुणों को तनाव पुनर्प्राप्ति दर, तनाव पुनर्प्राप्ति दर आकार स्थिरता आदि के संदर्भ में रिपोर्ट किया जाता है। विभिन्न निश्चित तापमानों पर विभिन्न प्रकार के आकार बनाए रखने की इसकी अनूठी गुणों का उपयोग सक्रियण प्रणालियों के लिए प्रभावी ढंग से किया जा सकता है। एसएमई प्रभाव एसएमए में मुख्य रूप से दो चरणों द्वारा प्रस्तुत किया जाता है जो मार्टेंसाइट से ऑस्टेनाइट और इसके विपरीत में परिवर्तन होते हैं और यह परिवर्तन या तो (i) तापमान परिवर्तन के कारण होता है जिसके परिणामस्वरूप एक तरफा आकार मेमोरी और/या दो तरफा आकार मेमोरी उत्पन्न होती है या (ii) उत्पन्न होती है ऑस्टेनिटिक चरण में भार लागू करके एसएमए में मार्टेंसिटिक फेस जो बड़े उपभेदों को संग्रहीत करने में सक्षम है। एसएमए के ये गुण और कारण बहुत अधिक ऊर्जा घनत्व प्रदर्शित कर रहे हैं; इसलिए एसएमए आधारित एक्चुएटर्स अन्य प्रकार के एक्चुएटर्स के विकल्प के रूप में कॉम्पैक्ट और हल्के होते हैं।

एक आधुनिक कार में, कार के विभिन्न कार्यों को नियंत्रित करने के साथ-साथ ड्राइवर को आराम/सुरक्षा प्रदान करने के लिए विभिन्न प्रकार की कुंडी का उपयोग किया जाता है। एक कुंडी का उपयोग यांत्रिक फास्टनर के कार्य को करने के लिए किया जाता है जो या तो यांत्रिक लीवर या विद्युत उत्तेजना द्वारा संचालित होता है। एक ऑटोमोबाइल में कई विशेष-उद्देश्यीय कुंडी शामिल होती हैं जैसे कि दरवाजे, हुड/बोनट, ट्रंक/बूट दरवाजा और पेट्रोल टैंक ढक्कन आदि के घटक । वर्तमान में, अधिकांश कुंडी या तो केबल तार के माध्यम से तनाव लागू करके या इलेक्ट्रो-मैकेनिकल माध्यमों से यांत्रिक रूप से संचालित होती हैं। जो डीसी मोटर या सोलनॉइड द्वारा सक्रिय होता है। वाहन की कुंडी को सक्रिय करने के लिए इन एक्चुएटर्स को वैकल्पिक एसएमए तकनीक से प्रतिस्थापित किया जाता है । पिछले कुछ वर्षों से सीएसआईआर-एम्प्री इस क्षेत्र में सक्रिय रूप से काम कर रहा है और स्मार्ट सामग्री विकसित की गई है। 12वीं पंच वर्षीय योजना और अनुवाद (ट्रांस्लेश्नल) परियोजना के निष्पादन के दौरान, सीएसआईआर-एम्प्री ने स्मार्ट सामग्री आधारित एक्चुएटर विकास में विशेषज्ञता विकसित की है, विशेष रूप से तार के रूप में नितिनोल आकार मेमोरी मिश्र धातु का उपयोग करते हुए। ऑटोमोबाइल के लिए दरवाज़ा कुंडी असेंबली को लॉक करने-अनलॉक करने, वाहन/कार के लिए ईंधन भरने वाले दरवाजे/पेट्रोल ढक्कन रिलीजिंग एक्ट्यूएटर और डिकी रिलीजिंग एक्ट्यूएटर सिस्टम के लिए एक्चुएटर्स विकसित किए गए थे। इन एक्चुएटर्स को डिजाइन और विकसित किया गया था और कारों में उनका परीक्षण और परीक्षण चल रहा है। विकसित एक्चुएटर्स के आंकड़े नीचे दिखाए गए हैं और परीक्षण और परीक्षण के साथ-साथ प्रौद्योगिकी का प्रदर्शन करने के लिए कार के दरवाजे में एक प्रोटोटाइप एक्चुएटर स्थापित किया गया था। परिवर्तन तापमान प्राप्त करने के लिए विद्युत प्रतिरोधक ताप विधि सबसे उपयुक्त और आसानी से नियंत्रित विधि है।

इन एक्चुएटर्स के डिज़ाइन और विकास में नगण्य यांत्रिक भाग होते हैं जिनमें आकार मेमोरी मिश्र धातु तत्व, गोलाकार और/या आयताकार क्रॉस सेक्शन में यांत्रिक बल संचारण लीवर और पुली शामिल होते हैं। एसएमए तत्वों को द्विदिशात्मक रैखिक गति के लिए विरोधी/विपरीत प्रकार की व्यवस्था में व्यवस्थित किया गया है। लीवर की गति वाहन के दरवाजे की लॉक या अनलॉक स्थिति के लिए लैचिंग प्रणाली को सक्रिय करती है। इस एक्चुएटर डिवाइस का उपयोग मैकेनिकल लॉक लैच असेंबली को लॉक करने और अनलॉक करने के लिए किया जा सकता है, उदाहरण के लिए वाहन डोर लैच, कार सेंट्रल सिक्योरिटी लैच, होम डोर लैच या इसी तरह के। इस एक्चुएशन डिवाइस के संचालन को एक इलेक्ट्रॉनिक नियंत्रण प्रणाली के माध्यम से नियंत्रित किया जाएगा जो या तो सीधे बटन या रिमोट कुंजी बटन से संचालित होता है जैसा कि ब्लॉक आरेख में दिखाया गया है।